According to the latest ink market data released by WTiN, Joseph Link, an expert in the digital textile field, analyzed the core trends of industry development and key regional data.

The digital textile printing ink market has broad prospects but also faces numerous challenges that will impact its development path in the coming years.

With the widespread adoption of digital printing technology in fashion, sportswear, and home textiles, the demand for high-quality ink continues to rise. However, complex market dynamics pose obstacles for manufacturers and suppliers.

OBOOC Direct-to-Garment ink with imported

Volatile Raw Material Costs

Digital ink production relies on specialized pigments and chemicals, with prices heavily impacted by supply chain disruptions, geopolitical conflicts, and environmental policies. While Chinese ink manufacturers benefit from raw material supply advantages, price fluctuations continue to erode profit margins and drive up downstream textile production costs.

Mounting Environmental Pressures

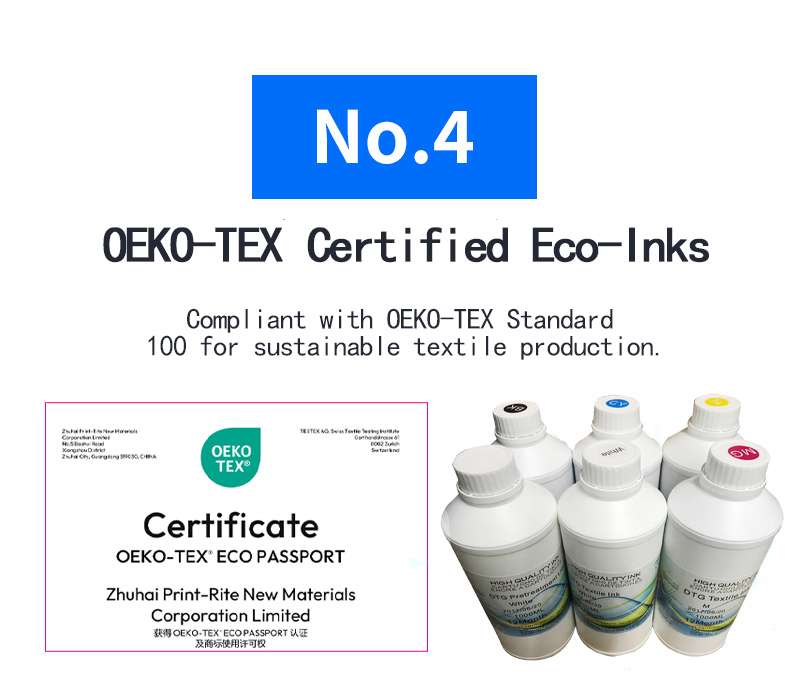

As one of the world’s major polluters, the textile industry faces heightened scrutiny over digital ink’s environmental impact. Despite surging demand for water-based inks and biodegradable formulations, the transition requires substantial R&D investment, and production process adjustments may slow market adoption.

Regional Demand Divergence

Asia, Europe, and the Americas exhibit distinct growth patterns: Asia leads in consumption volume, while Europe and America prioritize high-value applications. This necessitates regionalized strategies from ink suppliers, requiring customized solutions to address diverse market needs.

Digital Textile Ink: Promising Yet Challenging

Approximately 25% of ink used in digital printing processes is not absorbed by fabrics and becomes waste. Although recycling technologies exist to reuse this ink, they face significant implementation challenges.

Water-based inks, while biodegradable, suffer from performance instability after recycling and short shelf life. High-precision filtration systems entail prohibitive costs and technical limitations, while ink extraction techniques that preserve fabric integrity remain under development.Yet, ink recycling holds significant potential to reduce resource waste, and may become an industry sustainability standard. Facing these challenges, the digital printing ink market must pursue continuous innovation to achieve sustainable growth.

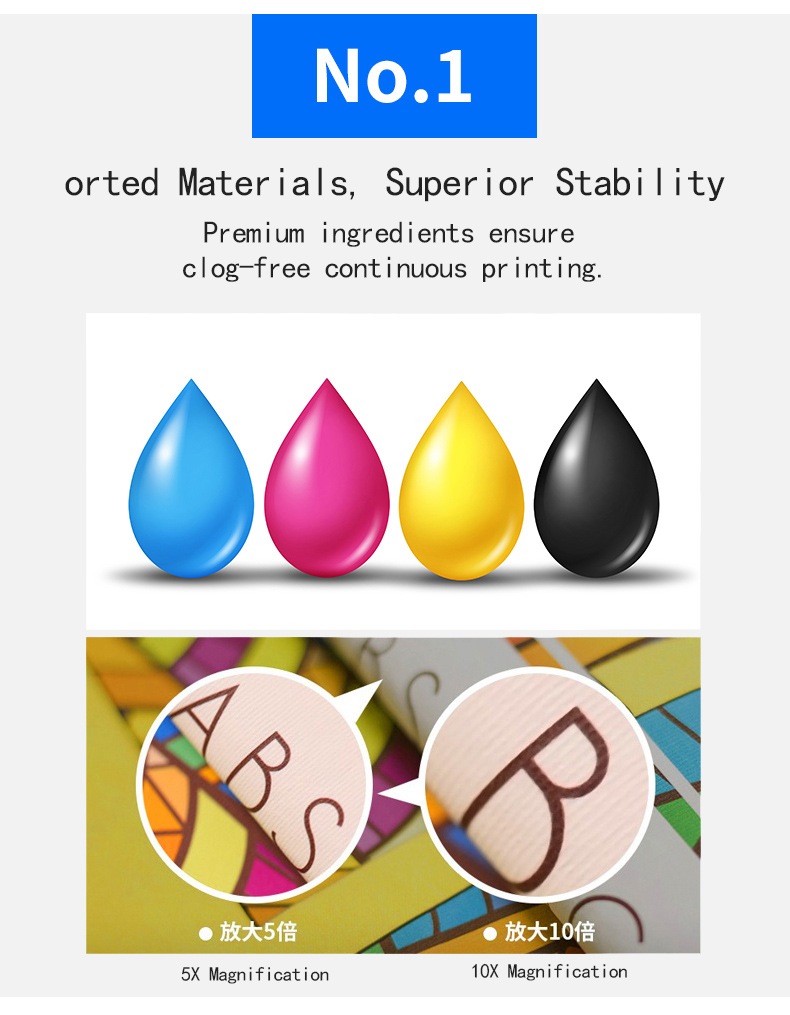

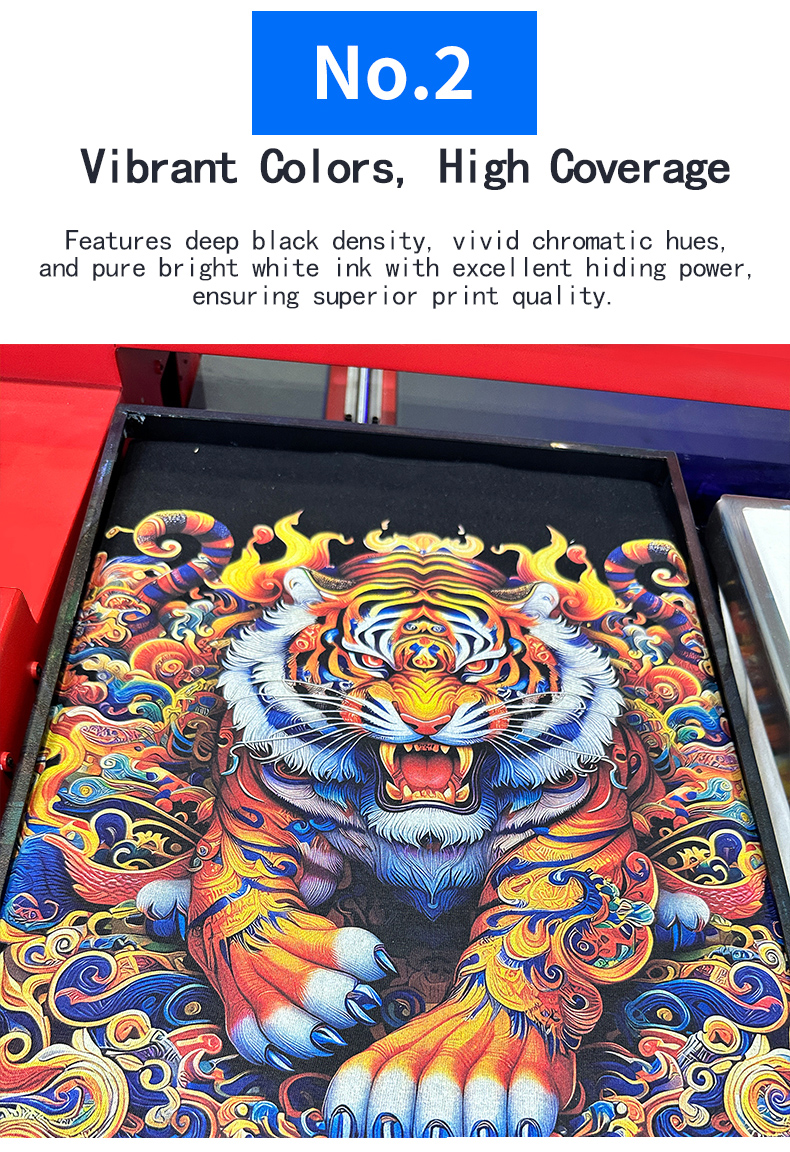

OBOOC, a high-tech enterprise specializing in domestic ink production, dedicates 10%-15% of its annual net profit to R&D to strengthen innovation and enhance product competitiveness. The company’s Direct-to-Garment ink is a high-performance formula developed from premium imported raw materials.

1.Vibrant Colors: Finished products exhibit richer, more vivid hues with long-term color stability even after extended storage.

2.Ultra-Fine Ink Particles: Multi-stage filtered to nano-scale precision, ensuring zero nozzle clogging.

3.High Color Yield: Directly reduces consumable costs while maintaining soft fabric hand feel.

4.Exceptional Stability: Achieves international Grade 4 wash fastness, with proven performance in waterproofing, wet/dry rubbing resistance, wash durability, lightfastness, and opacity through rigorous testing protocols.

5.Eco-Friendly & Low Odor: Complies with international environmental standards.

Post time: Jun-12-2025