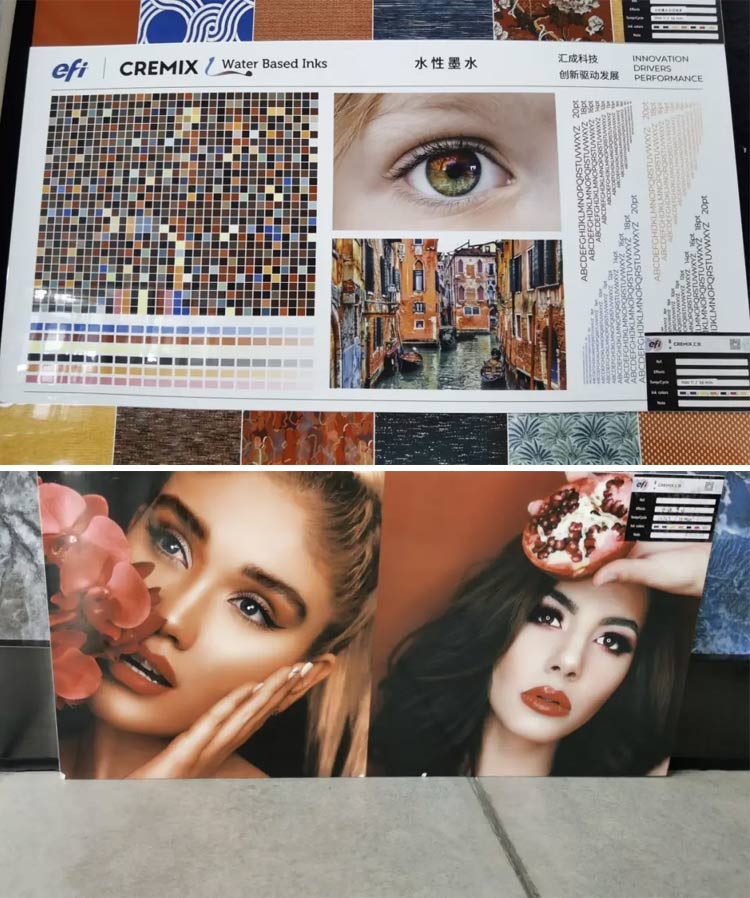

We see on the street those colorful rich, realistic large-format ads, are photo machine printing.And according to different use scenarios we use the ink is not the same, today xiaobian to give you a simple explanation of the pictorial machine with ink a few differences:

Photo machine is most commonly used to the oily ink pigment dilution in oil, such as mineral oil, vegetable oil, ink on the printing medium by oil penetration and evaporation pigment attached to the medium;Water-based ink is water as the dispersion medium, ink on the printing medium through the infiltration and evaporation of water pigment attached to the medium.

Photo machine is most commonly used to the oily ink pigment dilution in oil, such as mineral oil, vegetable oil, ink on the printing medium by oil penetration and evaporation pigment attached to the medium;Water-based ink is water as the dispersion medium, ink on the printing medium through the infiltration and evaporation of water pigment attached to the medium.

Photo industry ink according to the use to distinguish, can be divided into two kinds:One is water-based ink, which is mainly composed of water and water-soluble solvents.

The other is, oily ink, insoluble solvent as the main component of the dissolved color base.

According to the solubility of solvent, it can also be divided into three types:

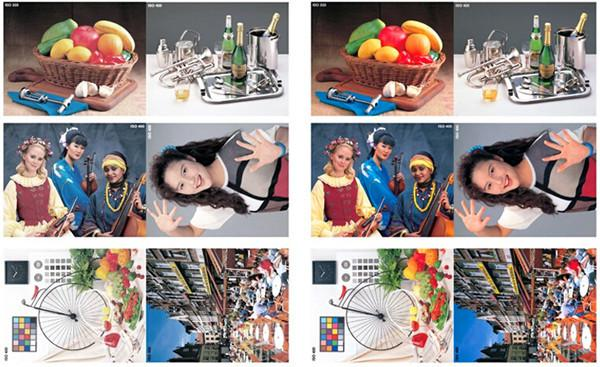

First, dye ink: it is dye based ink, most indoor photo machines are in use;

Two, pigment ink: it is based on pigment ink, used for outdoor printing machine.

Three, weak solvent ink: between the two, used for outdoor photo machine.

Special attention should be paid to the fact that these three inks cannot be used together. Water-based machine can only use water-based ink, and oil-based machine can only use weak solvent ink and solvent ink. Since the ink cartridge, pipe and nozzle of water-based machine and oil-based machine are different when the machine is installed, the ink cannot be used randomly.

The factors affecting the quality of ink mainly have five aspects: dispersant, conductivity, PH value, surface tension, viscosity.

1) dispersant: is a surfactant, its role is to improve the physical properties of the ink surface, enhance the affinity of ink and sponge, moisture.So generally through the sponge storage, conduction of ink contains dispersants.

2) Electrical conductivity: this value is used to reflect its salt content.Better quality inks should not contain more than 0.5% salt to avoid crystallization at the nozzle.Oily ink according to the particle size of pigment, decide to use what nozzle, large spray machine 15PL, 35PL is according to the particle size to determine the accuracy of inkjet machine, this is very important

3) PH value: refers to the liquid PH, the more acidic the solution, the lower the PH value, on the contrary, the more alkaline the solution, the higher the PH value.In order to prevent ink corrosion nozzle, PH value should generally be between 7-12.

4) surface tension: can affect the formation of ink droplets, good quality ink is low viscosity, high surface tension.

5) viscosity: that is, the resistance of liquid flow, the viscosity of ink is too large, will make the printing process of ink supply

interruption;Viscosity is too small, will produce ink flow in the printing process. Ink at normal room temperature, generally can be saved for 3-6 months, too long time or precipitation, and affect the use or plug, ink preservation requirements sealed, avoid direct sunlight, temperature should not be too high or too low.

Post time: Sep-06-2021