Inkjet platemaking uses the principle of inkjet printing to output the color-separated files to a dedicated inkjet film through a printer. The inkjet ink dots are black and precise, and the dot shape and angle are adjustable.

What is film platemaking ink?

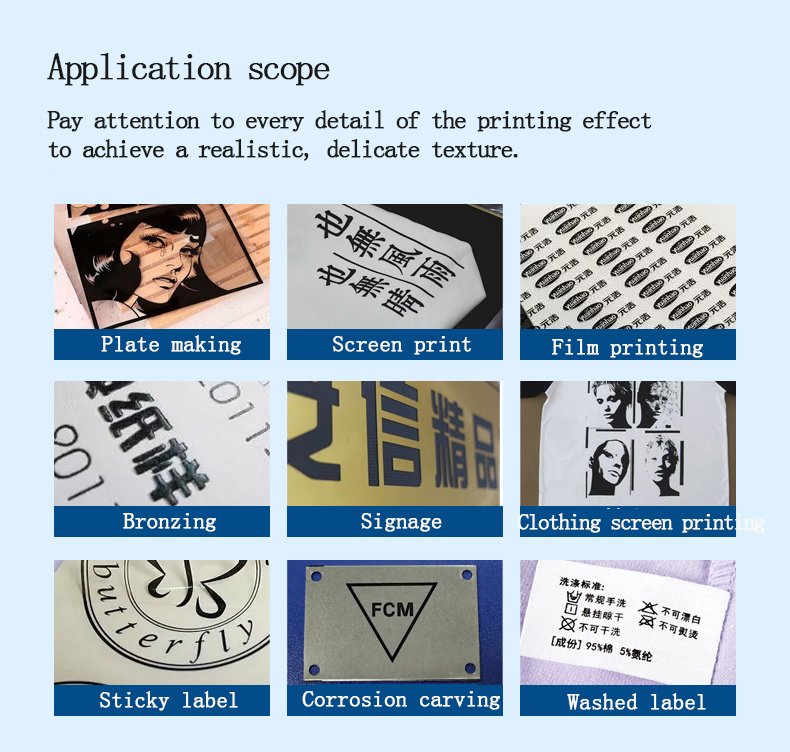

Film platemaking ink is a specialized inkjet ink for printing platemaking film. With high blackness, strong light-blocking properties, and stable performance, it creates precise patterns on the film used in subsequent exposure and printing processes. It is widely applied in various printing fields such as offset, screen, flexographic, embossing, self-adhesive, local glazing, textile printing, hot stamping, and monochrome printing.

Film plate making ink can be widely used in the printing industry

Precisely control ink dots and volume for accurate output.

Through the equipped software, the printer can be driven to precisely control the ink volume, ink drop size, dot angle, etc. Intelligent ink drop control technology makes the output film dots solid, sharp and without losing dots. Fine lines and small text can be perfectly presented.

Precisely control ink dots and volume for accurate output.

Through the equipped software, the printer can be driven to precisely control the ink volume, ink drop size, dot angle, etc. Intelligent ink drop control technology makes the output film dots solid, sharp and without losing dots. Fine lines and small text can be perfectly presented.

Film plate making ink has high purity, good blackness, and is environmentally friendly and safe

Specialized nanoscale water-based pigment printing ink

AoBoZi Film Platemaking Ink is a special nano-level water-based pigment printing ink with high purity, good blackness and strong coverage. Printing on a special film is comparable to the output effect of traditional film.

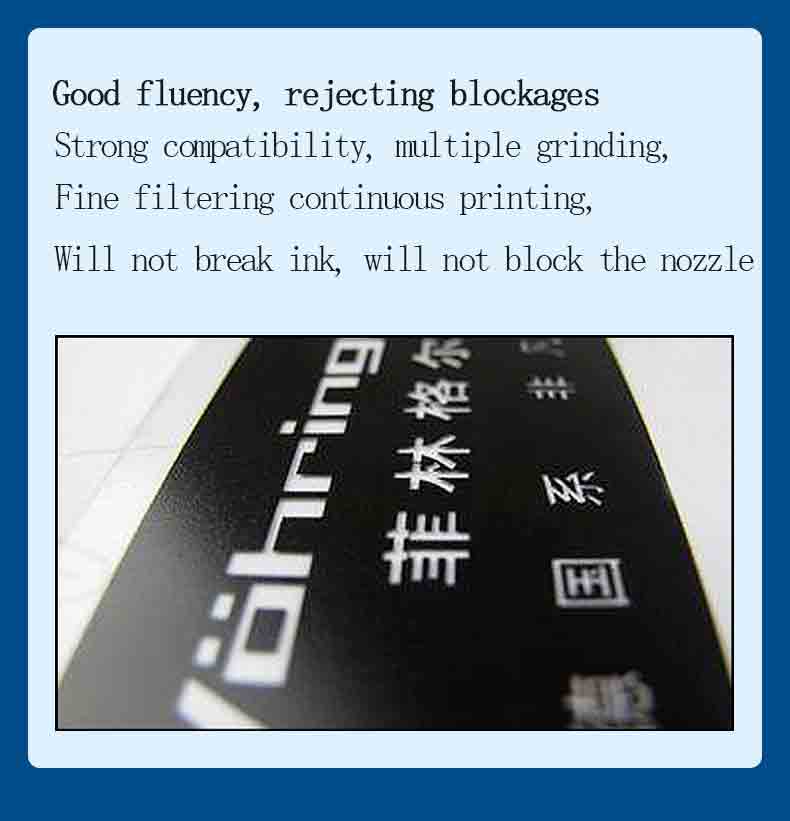

1. Good fluency and no clogging: strong compatibility, multiple grinding, fine filtration, continuous printing, no ink break, no nozzle clogging.

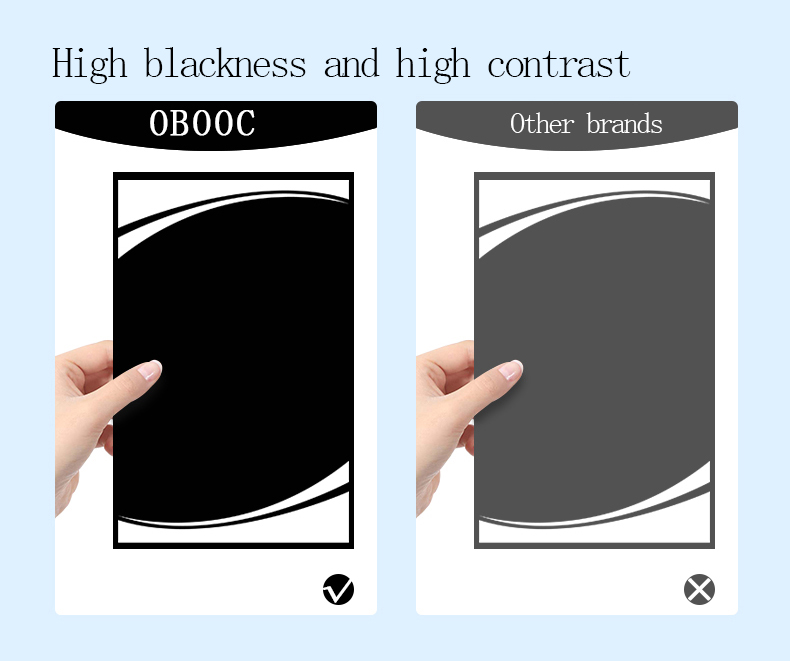

2. High blackness, high contrast: high blackness OD value, clearer printing, strong UV blocking, high density, fine and smooth, opaque.

3. Eco-friendly and safe with stable quality, this product uses high-quality raw materials, contains no harmful chemicals, has low odor, and prolongs nozzle life.

4. Good adsorption and strong compatibility: suitable for all types of piezoelectric hot bubble inkjet machines.

Strong compatibility, multiple grinding, continuous ink, no clogging of the nozzle

Post time: Jul-10-2025