The application scenario determines the winner, and in the field of UV printing, the performance of UV soft ink and hard ink often compete. In fact, there is no superiority or inferiority between the two, but complementary technical solutions based on different material characteristics. From leather to glass, from soft film to metal, using the appropriate type of UV ink is the best choice for achieving high-quality printing.

Flexibility Ink: The "Master of Extension" for Flexible Materials

UV flexibility ink offers two main advantages: extensibility and weather resistance. Its molecular-level flexible formula ensures the ink layer remains intact when materials like knife scraping cloth, light strips, and car stickers are bent or folded. For example, printed patterns on outdoor advertising light boxes remain crack-free even after being folded 180 degrees and can withstand over three years of UV aging. Additionally, soft ink provides 30% higher color saturation than traditional ink, enabling smooth gradient transitions on leather for high-end custom applications.

Flexibility ink is ideal for printing gradient coatings on car stickers. Tests show that patterns remain intact and colorfast after 50,000 kilometers of driving in temperatures ranging from -30 °C to 60 °C. These properties make it a top choice for flexible packaging and wearable devices.

Flexibility Ink: The "Master of Extension" for Flexible Materials

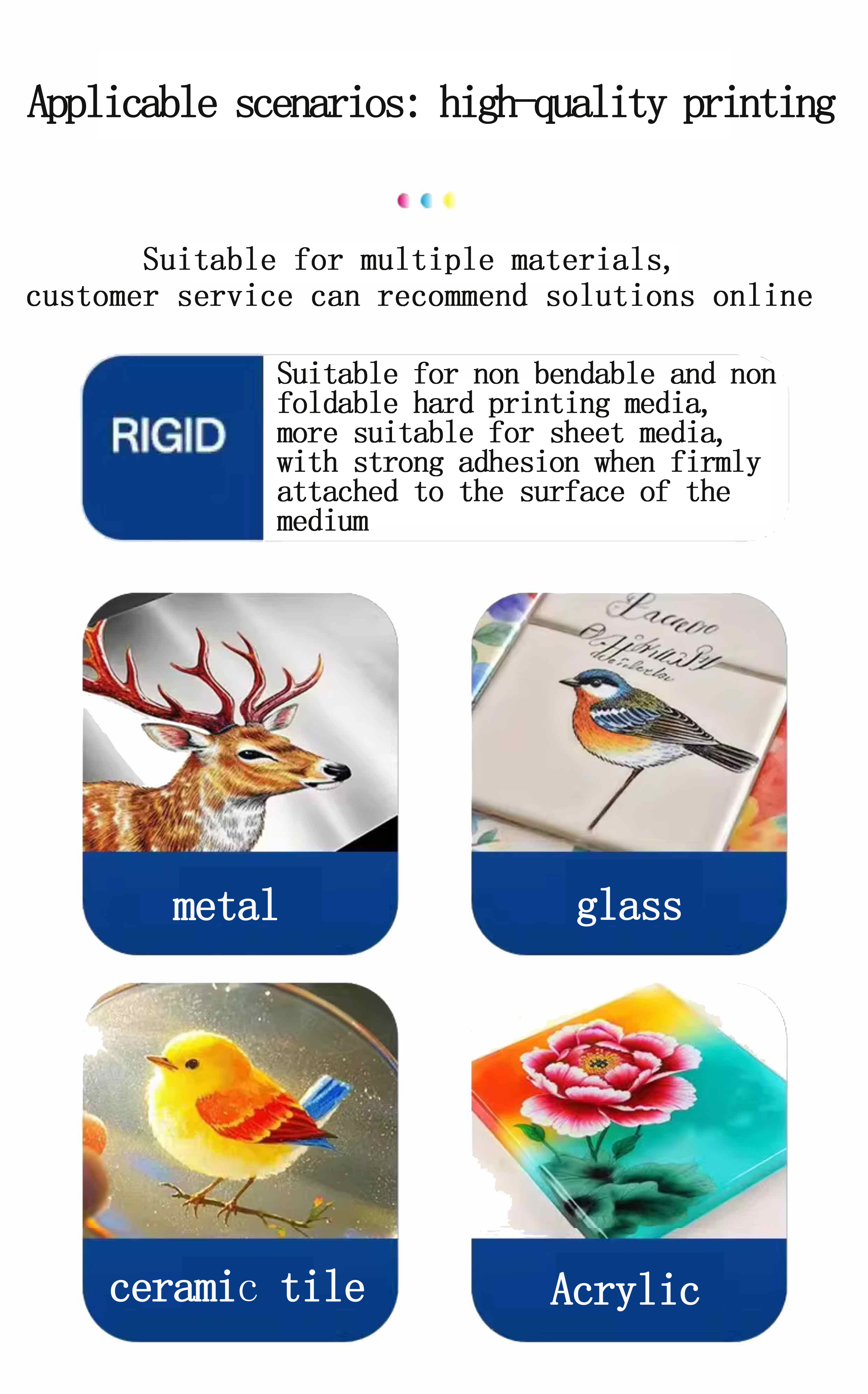

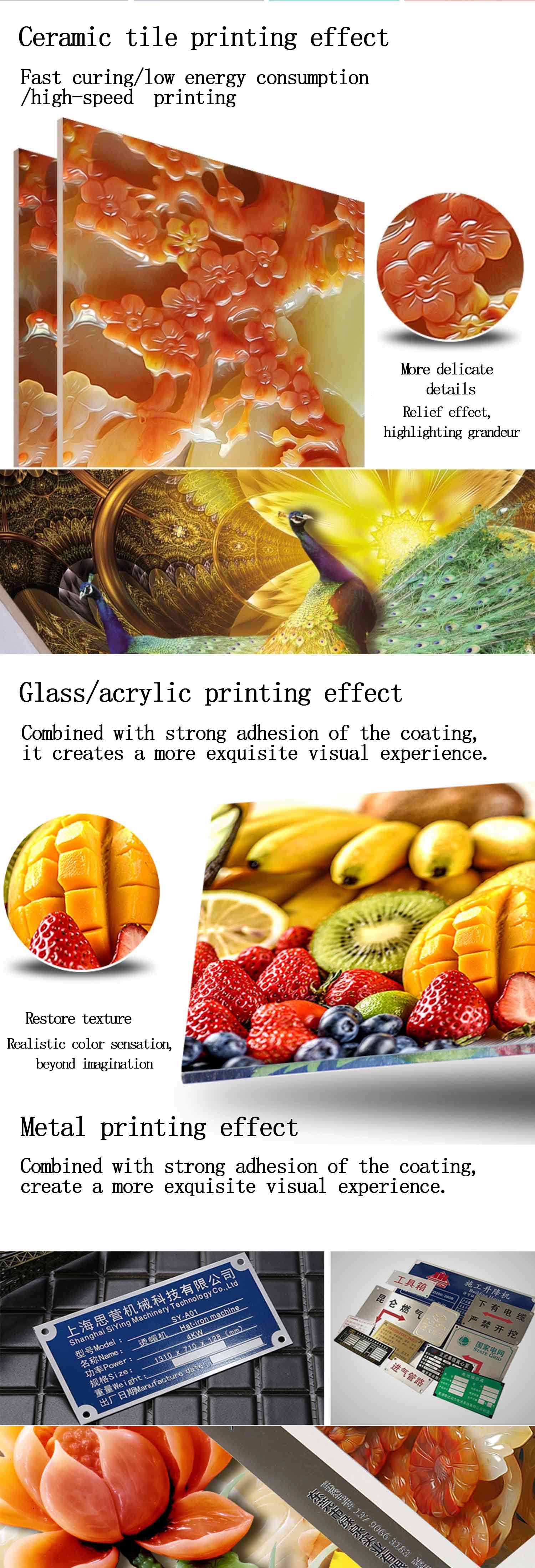

Rigid ink: the "king of adhesion" on hard surfaces

Rigid ink stands out for its strong adhesion and three-dimensional effect. Using nanoscale penetration, it chemically bonds to hard surfaces like metal, glass, and acrylic. For example, printed stainless steel signs can reach 3H pencil rigid after UV curing and remain clear after 2000 steel wool rubs. In tile printing, rigid ink creates a 0.5mm raised relief, improving both touch and visual appeal.

Rigid ink: the "king of adhesion" on hard surfaces

Aobozi UV ink achieves a breakthrough in the performance of flexibility and rigid inks through a three-stage filtration system and color separation wavelength control technology.

(1) Environmentally friendly formula: using high-quality imported environmentally friendly raw materials, no VOC, no solvents, and no irritating odors.

(2) Fine ink quality: After filling with a three-stage filtration system, impurities and particles in the ink are removed, resulting in excellent fluidity and ensuring no clogging of the nozzle.

(3) Vibrant colors: Wide color gamut, natural color transitions, when used with white ink, can print beautiful relief effects.

(4) Stable ink quality: not easy to deteriorate, not easy to precipitate, and has strong weather resistance and not easy to fade. The UV ink of black series can reach a sun resistance level of 6, while the color series can reach level 4 or above.

Aobozi UV ink achieves a breakthrough in the performance of flexibility

Post time: Aug-01-2025