In modern industrial production, product labeling is ubiquitous, from food packaging to electronic components, and coding technology has become an indispensable part. This is due to its many outstanding advantages:

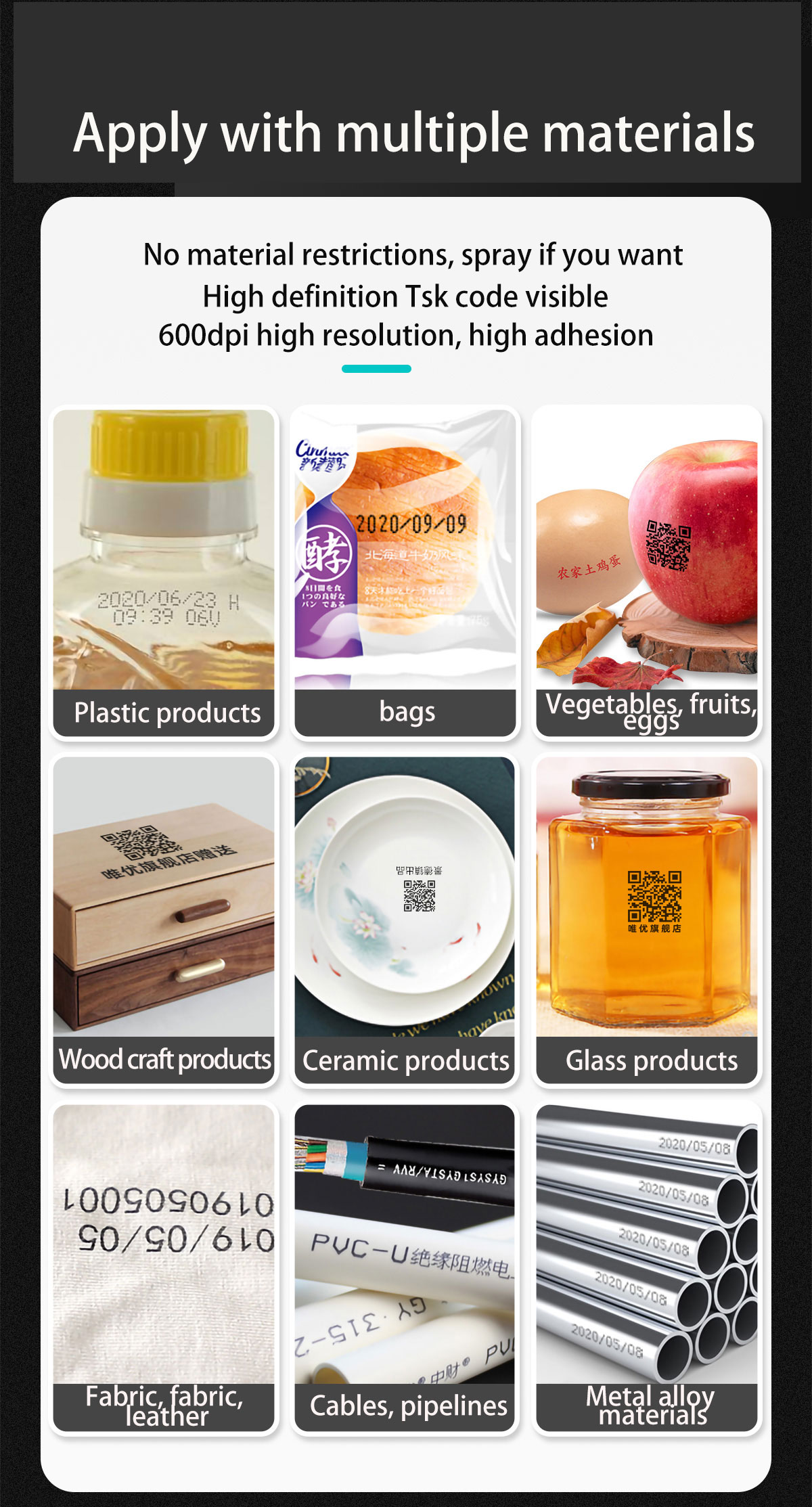

1. It can spray visible markings on various materials, including plastic, metal, paper, and wood.

2. It works well on rough or uneven surfaces with minimal surface preparation.

3. The nozzle-to-product distance varies slightly within 20 mm, with no significant impact on code readability.

4. Different inks enable a range of colors, such as red, yellow, green, and blue.

5. It supports high-speed printing, up to 2 meters per second for single-line text, ideal for integration with production lines.

6. The compact, flexible nozzle allows coding from any angle.

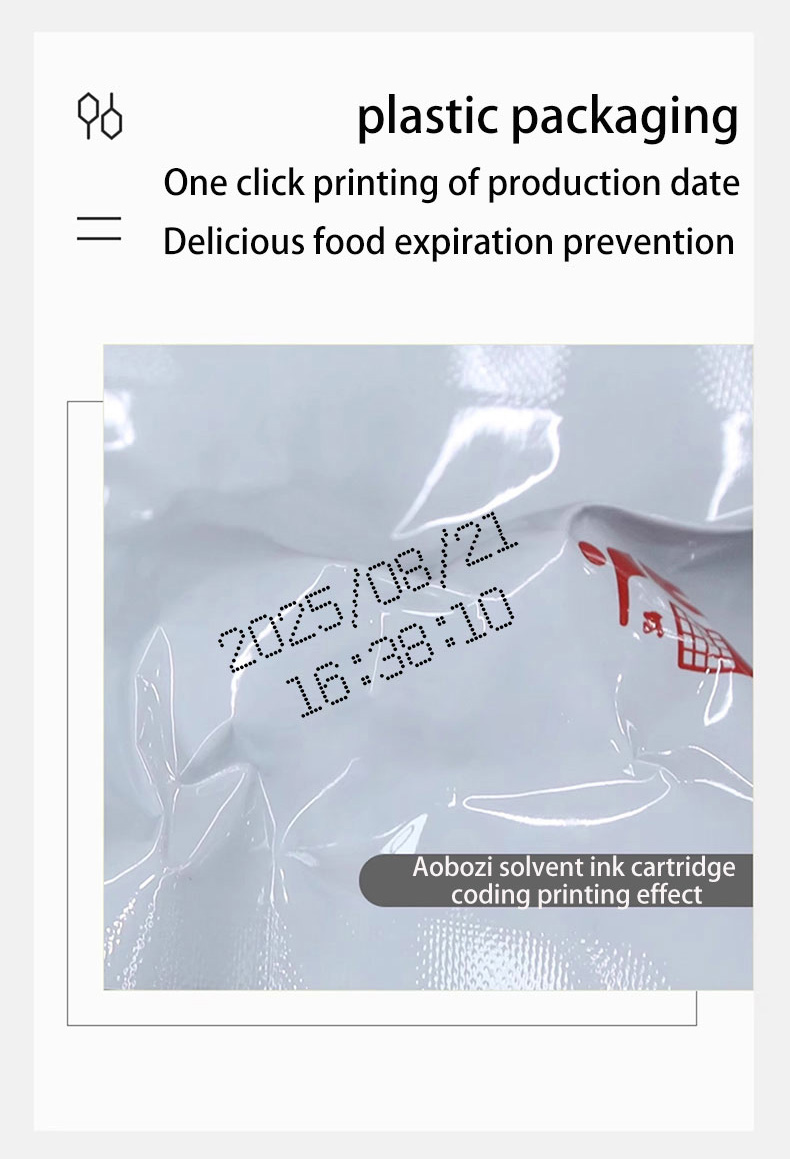

However, when marking with coding on flexible packaging, attention should be paid to the issue of ink permeability.

For example, the Swiss Food Packaging Act, which came into effect on May 1, 2017, sets one of the strictest food packaging standards in the world.

It specifies that substances in food packaging, including ink, must not migrate into food to avoid potential health risks. Ink is considered safe only if: the packaging does not directly contact food (e.g., outer shipping boxes); the material is non-permeable (e.g., glass or metal); or testing confirms no migration. Additionally, ink components must comply with legally permitted substances, which may limit the use of certain inks in flexible packaging.

In response to these regulations, specialized ink products for high-demand industries have entered the market. For example, Aobozi inkjet printer ink uses a solvent-based formula and is suitable for non-permeable surfaces such as metal, plastic, wood, and aluminum film. The printed markings are clear, durable, and widely used in food, pharmaceutical, beverage, and packaging printing.

It offers fine, stable ink quality, high viscosity to resist clogging, vibrant colors with excellent color rendering, high purity, and eco-friendly, pollution-free properties. It dries quickly without heat and is waterproof, light-resistant, and smudge-proof, ensuring reliable performance in challenging environments.

Post time: Oct-29-2025