Why choose us as your manufacturer

Our advantage

About some common questions

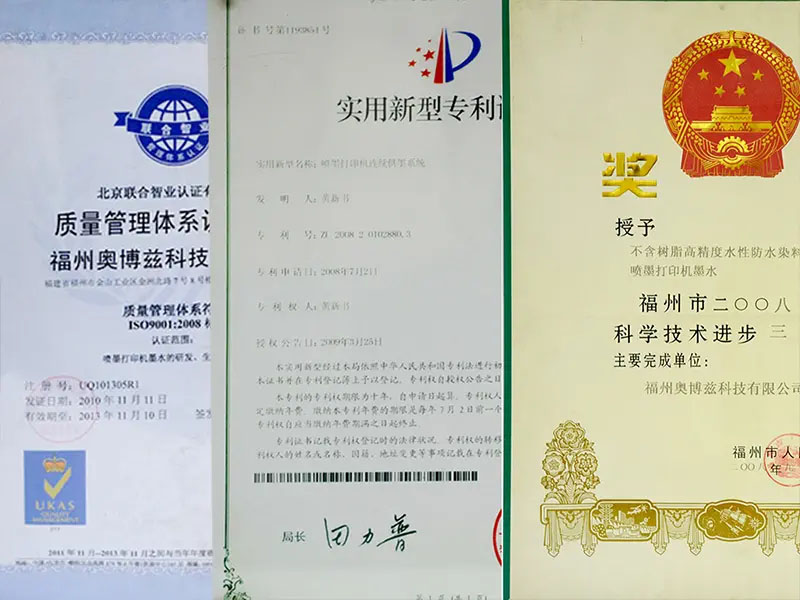

Our design team composed of more than 20 designers and engineers,

every year we created more than 300 innovative designs for the market, and will patent some designs.

-

What is a coder printer?

A batch printing machine attaches important information to your products by applying a mark or a code onto packaging or onto the product directly. This is a high speed, non contact process that places the coding machine at the heart of your business success.

-

What is the difference between barcode printer and ordinary printer?

There are many materials that barcode printers can print, such as PET, coated paper, thermal paper self-adhesive labels, synthetic materials such as polyester and PVC, and washed label fabrics. Ordinary printers are often used to print ordinary paper, such as A4 paper. , receipts, etc.

-

What is the difference between CIJ and Tij printers?

TIJ has specialized inks with fast dry time. CIJ has a wide variety of inks for industrial applications with fast dry time. TIJ is the best choice for printing on porous surfaces such as paper, cardboard, wood, and fabric. Dry time is very good even with mild inks.

-

What is the use of inkjet coding machine?

A coding machine can help you label and date packages and products efficiently. Inkjet coders are among the most versatile packaging printing devices available.