It is very common in today’s society that you will find one man whose clothes is similar with you in five step and find Your clothes are the same as others in ten step.How can we avoid the embarrassing phenomenon?Now people begin to customized their own pattern on clothes.Heat transfer paper will satisfy people’s need.

Think of heat transfer paper as a type of fabric sticker, you can print any pattern on the paper with your home inkjet printer and then apply it to fabrics with 100% natural content.The paper has special heat transfer technology that uses heat to fuse your printed design to your fabric by pressing it with a heat press or hand iron.

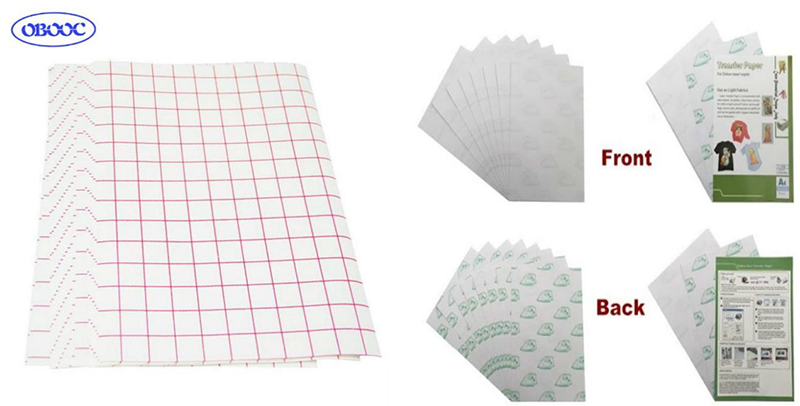

The choice of heat transfer paper should accordance with the fabric color,you can use the transparent heat transfer paper if the fabric color is light.White heat transfer paper is used when applying to darker colored fabrics. Because it can prevent the dark fabric colors from showing through the transfer.

If you are using transparent heat transfer paper,you will need to mirror your image as the printed side of the paper that will be placed down onto the fabric you are working with.However, if you are using white heat transfer paper you will not need to mirror your image as the printed side of your paper because it will face up when applying to the fabric you are working with. You should remember one thing before you use white heat transfer paper is remove the backing from the heat transfer paper.

Begin to transfer when you complete these steps:

1. Preheat the heat press,the temperature should be set between 177°to 191°.

2. The pressure of the press is based on the thickness of the fabric.Generally,a lot of fabric be suiteable to medium press or high press.

3. There are different time associated with different type of heat transfer paper.You can use following time as a guide: ①Inkjet Transfer Paper: 14 – 18 seconds ②Dye Sublimation Transfer: 25 – 30 seconds

③Digital Appliqué Transfer: 20 – 30 seconds ④Vinyl Transfer: 45 – 60 seconds

1. Put you product on plate and place the transfer paper face up on the desired location of your product within the pressing area. For applique transfer and vinyl transfer you will need to cover the transfer paper with a thin cloth to protect it.

2. Press the produc,remove the film after the time end.Just like that,your heat pressed custom apparel is complete

Avoid common mistakes

● Forget mirror image

● Printing on the non-coated side of paper

● Ironing the image or text on an uneven or not solid surface

● The hot of heat press is not enough

● The press time is not enough

● The pressure is not enough

Post time: Jul-03-2023