Inkjet Printer Ink

-

Inkjet Printer Ink

Inkjet Printer InkPigment Ink for Epson/Mimaki/Roland/Mutoh/Canon/HP Inkjet Printer Print

read more -

Inkjet Printer Ink

Inkjet Printer InkInvisible UV Inks for Epson Inkjet Printer, Fluorescent under UV Light

read more -

Inkjet Printer Ink

Inkjet Printer InkUV LED-curable Inks for Digital Printing Systems

read more -

Inkjet Printer Ink

Inkjet Printer InkOdourless Ink For Solvent Machines Starfire, Km512i, Konica, Spectra, Xaar,Seiko

read more -

Inkjet Printer Ink

Inkjet Printer InkWaterproof Non Clogging Pigment Ink for Inkjet Printer

read more -

Eco Solvent Ink

Eco Solvent InkEco-solvent ink for Eco-solvent printer with Epson DX4 / DX5 / DX7 Head

read more -

Dye Ink

Dye Ink100ml 6 Color Compatible Refill Dye Ink for Epson 11880 11880C 7908 9908 7890 9890 Inkjet Printer

read more -

Inkjet Printer Ink

Inkjet Printer InkOutdoor Solvent Ink for Konica Seiko Xaar Polaris Print Head for Flora/Allwin/Taimes Printing

read more -

Eco Solvent Ink

Eco Solvent InkEnvironment Friendly Eco Solvent ink for Roland Muthoh Mimaki Epson Wide Format Inkjet Printer

read more -

Dye Ink

Dye Ink100ml 1000ml Universal Refill Dye Ink for Epson/Canon/Lemark/HP/Brother Inkjet Printer

read more -

Inkjet Printer Ink

Inkjet Printer InkPrinting On Metal Plastic Glass Led UV Ink for Epson DX7 DX5 Printer Head

read more

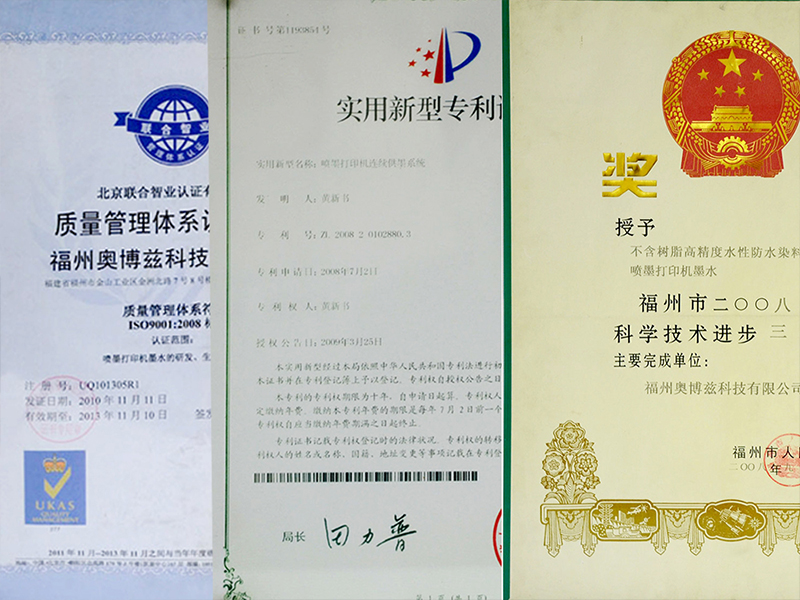

Why choose us as your manufacturer

About some common questions

Our design team composed of more than 20 designers and engineers,

every year we created more than 300 innovative designs for the market, and will patent some designs.

-

What is the difference between heat transfer and direct inkjet technology?

1. Printing speed: Direct inkjet printing is faster, making it suitable for large-scale production needs. 2. Printing quality: Heat transfer technology can produce high-resolution images for complex graphics. In terms of color reproduction, direct inkjet offers more vibrant colors. 3. Substrate compatibility: Direct inkjet is suitable for printing on various flat materials, while heat transfer technology can be applied to objects of different shapes, sizes, and surface materials.

-

Is the transfer efficiency of OBOOC sublimation transfer ink high?

OBOOC sublimation transfer ink is recommended to be used with coating liquid to achieve highly efficient heat transfer, save ink during printing, and effectively maintain the softness and breathability of fabrics.

-

Which is Better: Dye Ink or Pigment Ink?

First, choose the right ink type based on your specific needs. The main advantage of dye ink is its ability to produce photo-quality prints with vibrant colors at a lower cost. Meanwhile, pigment ink excels in durability, offering excellent weather resistance, waterproofing, UV resistance, and long-lasting color retention.

-

What are the key advantages of eco-solvent ink compared to other printing inks?

Eco-solvent ink offers excellent material compatibility, enhanced safety features, low volatility and minimal toxicity. While maintaining the durability and weather resistance of traditional solvent inks, it significantly reduces VOC emissions, making it more environmentally friendly and safer for operators. The ink also delivers high-quality, precise printing results with vibrant colors.

-

Is the inkjet printing ink produced by OBOOC stable in performance?

OBOOC ink undergoes a triple filtration system during filling to ensure stable quality. It must pass repeated low- and high-temperature tests before leaving the factory, with the highest lightfastness rating reaching level 6.